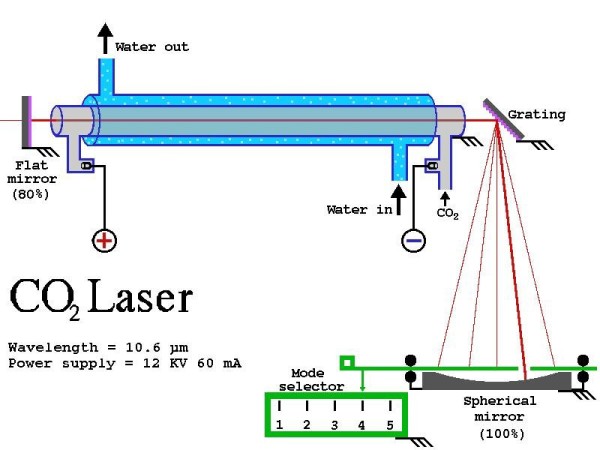

The acronym laser actually stands for light amplification by stimulated emission of radiation and a co2 laser emits a very small 10μm infrared cutting beam.

Disadvantages of co2 laser cutting.

This technology has become an essential part of manufacturing process.

Both processes offer increased precision and versatility for shops of all sizes and the technology is continually evolving toward improved precision easier use and greater flexibility.

The reason why engineers prefer a laser cutting service lies with the long list of upsides it offers the advantages of laser cutting are flexibility precision repeatability speed cost effectiveness great quality contactless cutting versatility and automation possibilities.

Advantages of laser disadvantages of laser.

The rapidly growing science of laser cutting is dominated by two main methods carbon dioxide co2 laser cutting and fiber laser cutting.

Learn some laser cutting advantages and disadvantages by diving into the technicalities of the process.

Its efficiency is better than he ne and argon laser types.

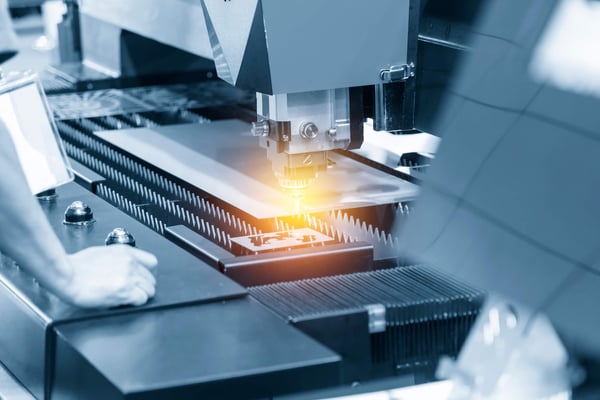

Laser cutting is typically used in a large industrial setting to cut materials such as metal and plastic.

Laser cutting does not require an exchange of tools for.

The advantages and disadvantages prove why it s popular.

The fiber optic cable which is made of silica glass uses a diode laser pump to reflect and amplify electrons into the powerful fiber laser beam that cuts your materials.

Small size per watt of output power.

It is very intense beam of light or.

Although it is able to produce a high quality cut and is very precise the laser cutting process has disadvantages.

It mentions benefits or advantages of laser and drawbacks or disadvantages of laser.

Following are the drawbacks or disadvantages of co2 laser.

Drawbacks or disadvantages of co2 laser.

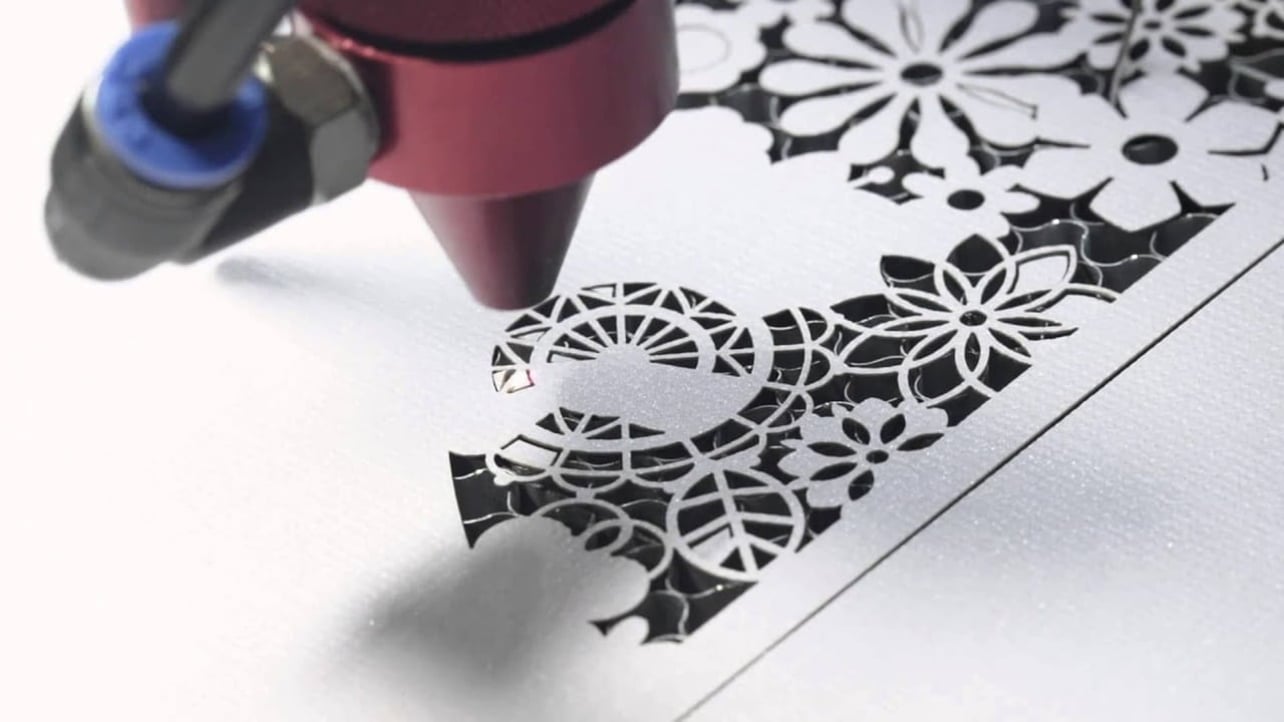

During the laser cutting procedure there is laser beam used to cut different materials like metal plastic wood rubber etc.

This method comes with its own share of advantages and disadvantages.

Laser cutting involves the use of a laser beam to cut materials like wood plastic metal rubber etc.

This technology has become an important part of a manufacturing process.

Laser cutting machines are equipped with computer controlled programming that determines how and where the interface is integrated in the material.

Laser term stands for light amplification by the stimulated emission of radiation.

This page covers advantages and disadvantages of laser and its types.

Laser cutting is an industrial process used in many different fields.

Divergence of co 2 laser is greater than he ne and argon laser.

Divergence is ranging from 1 to 10 milli radians.

The advantages of a co2 laser.

The typical co2 laser cutter is a pretty remarkable machine.

It uses a laser usually directed by a computer to melt or burn the material.

After bouncing around a series of mirrors and passing through focusing lenses the laser cutter concentrates several kilowatts of energy.